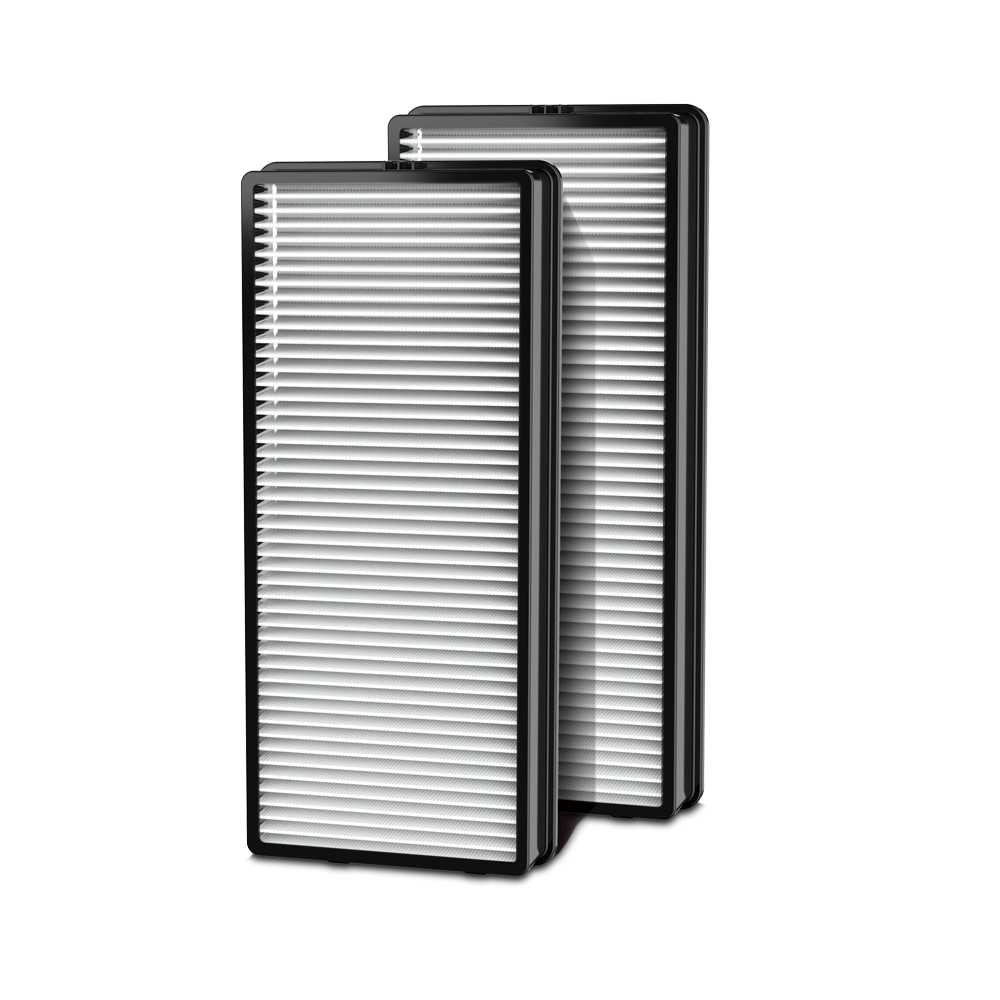

HEPA filters

High-efficiency particulate air system (HEPA system), particulate air-filtration system designed to capture at least 99.97 percent of fine airborne particles larger than at least 0.3 micrometer (0.00001 inch; 1 micrometer = 10−6 meter), as specified by the United States Department of Energy (DOE) and the European Committee for Standardization. The European standard is similar to the DOE standard; however, it defines five HEPA classes—H10 through H17—of increasing efficiency. The term HEPA filter refers not to a specific filter design but to the specific level of efficiency (i.e., 99.97 percent).

History and Use

HEPA filters were developed in the early 1940s and used first by the Manhattan Project to contain the spread of airborne radioactive contaminants. HEPA filters were introduced commercially in the following decade to eliminate viruses, bacteria, airborne fungi, pollen, human hair, and particulate matter (such as smoke particles, pet dander, and dust) from the air in buildings. HEPA filters grew in popularity and necessity as technological advances that accompanied the Cold War saw the growth of industries in need of highly efficient air filters, such as the computer, electronics, aerospace, and nuclear power industries. Hospitals and pharmaceutical manufacturers also kept the filters in high demand, while the emergence of strict air pollution laws in the United States and other countries beginning in the 1970s raised awareness about the importance of clean air.

HEPA filters have been installed in aircraft and in hospitals, greatly restricting the spread of airborne fungi, viruses, and bacteria. Aircraft filters help slow down the spread of diseases from city to city. HEPA filters in hospital settings and in other medical uses are typically rated higher than the DOE standard—often at 99.99 percent efficiency, H14 in the European system—and equipped with high-intensity ultraviolet lights that kill any bacteria and viruses that the filters trap.

Design

Unlike membrane filters, HEPA filters do not rely on the action of sieves or strainers, catching anything larger than a certain size while the rest passes through. Instead, they typically involve a pleated sheet of randomly arranged fiberglass fibers with diameters usually between 0.5 and 2 micrometers (between 0.00002 and 0.00008 inch). A motorized fan passes air through the filter, where particles are trapped when they adhere to the fibers or become embedded in them. The smallest particles collide with gas molecules. Such collisions slow the passage of those particles through the filter and increase their likelihood of becoming trapped. Air-purifying systems equipped with a HEPA filter trap particles; they do not dispose of them. Consequently, HEPA systems usually employ other processes as well to complete their work, such as high-energy ultraviolet light for degrading bacteria and viruses and a fan or other forced-air system to ensure that the air passes through the filter. Activated carbon is often used to adsorb small volatile chemical molecules, converting them to a solid state from a gaseous one; this has the additional effect of odor control. Ionizer purifiers, frequently sold for home use, generate electrically charged gas ions that attach to airborne particles and cause them to stick to a collector plate. Those devices also can be used in conjunction with or as an alternative to HEPA filtration.